5 major benefits of RFID technology for inventories

1. Considerable time savings

Forget tedious, time-consuming inventories. Unlike barcodes, RFID scanners scanners enable mass reading, scanning hundreds of items in just a few minutes, without the need to view them. For example, a 300m2 warehouse can be inventoried in just 3 minutes. This unrivalled speed enables you to save precious time by carrying out semi-automated inventories, boosting your productivity and cutting operating times.

2. Improved accuracy

No more manual counting errors. RFID provides up-to-date stock accuracy, virtually eliminating data entry errors. This enhanced accuracy ensures better management of your stocks or assets and greater confidence in your inventory data.

3. Cost reduction

Fewer errors, less time spent on stocktaking and improved inventory or asset management mean lower overall costs. The direct return on investment is around 18 months. Added to this is operational efficiency, reduced stress for staff and greater security in the management of sensitive equipment.

4. Enhanced data security

Unlike barcodes or QR codes, RFID makes it almost impossible to falsify data. The security of your stock is also increased tenfold, as the RFID tag can send out an alert if a product is moved when it shouldn't be. For example: anti-theft kiosks in stores.

5. Automation and simplified integration

The data collected is easily integrated into your ERP system. This integration facilitates process automation, reducing manual tasks and increasing operational efficiency.

Find out how RFID can help you geolocate your products !

RFID inventory case study

How RFID inventory works

Stocktaking with RFID technology requires a system based on the interaction of several key components. Here's a detailed look at each component and their role in the inventory process.

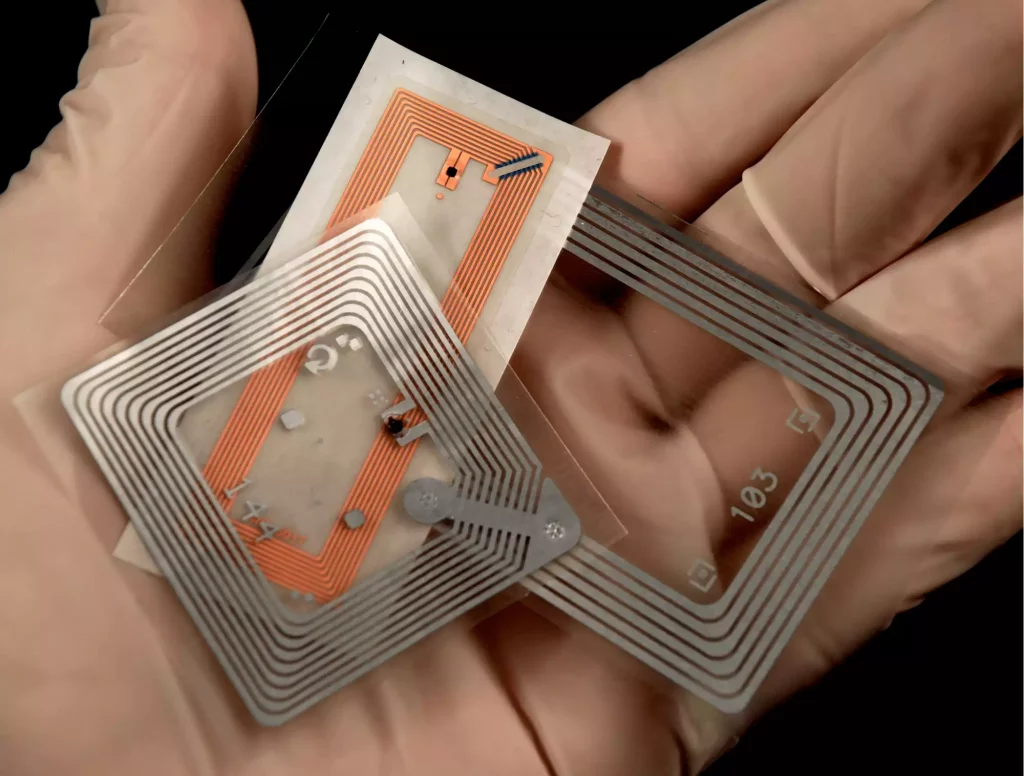

RFID tags: the heart of the system

- Tag types: There are two main types of RFID tag - active and passive. Active tags are powered by an internal battery and can transmit signals over longer distances. Passive tags, on the other hand, have no power source of their own, and are activated by energy from RFID readers. The tag can be integrated into a label, card or more robust support. Tag size has a direct impact on reading distance. A 30mm x 20mm label with an embedded tag can be read from up to 2-3 m away.

- Tag programming: Each tag is programmed with information unique to the item to which it is attached. This information can include product ID, date of manufacture, expiration date, and other relevant data.

- Durability and adaptability: RFID tags are designed to withstand harsh environments, and can be adapted to a variety of products, from small consumer items to large industrial equipment. The lifespan of a passive tag simply depends on the adhesive applied to the substrate. As the tag emits no waves, its lifespan can be counted in decades.

Readers: signal interpreters

- How the readers work: RFID readers send radio waves to activate tags and receive the information they contain. These readers can be fixed or portable, offering flexibility in the way inventory is carried out.

- Reading range and speed: Reading range and speed vary according to the type of reader and tag. Some systems can read hundreds of tags per second from several meters away, making inventory quick and efficient.

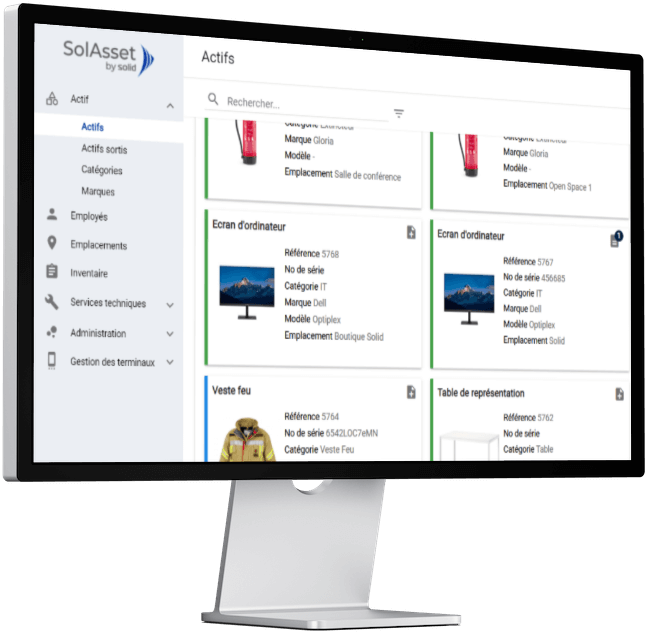

Management software: The analytical brain

- Data processing: Once the information has been captured by the readers, it is transmitted to the management software. This software is the brain of the system, processing and analyzing the collected data.

- Integration and analysis: The software can be integrated with other business management systems for comprehensive analysis. It provides detailed reports on inventory status or asset location, enabling companies to make informed decisions based on accurate data.

Steps to optimized inventory management

Needs analysis with the customer

The first step is to understand your specific needs. This involves analyzing your current inventory and warehousing processes, to identify challenges and opportunities for improvement.

Defining the right solution

Based on this analysis, we work with you to determine the most appropriate solution. This can include choosing technologies, customizing labels, selecting readers and antennas, and defining software requirements.

Software development and customization

Based on your requirements, we develop and adapt software that integrates seamlessly with your system. This software will be the heart of the solution, enabling you to manage your inventories easily and efficiently.

On-site equipment installation

Traceability via passive RFID requires no specific infrastructure. The RFID tag is incorporated into your labels during production, and the antennae for reading it are the size of a 1D/2D code reader. In some environments, it's worth adding fixed antennas. In this case, we ensure that they are perfectly integrated into your working environment.

Training and support

Once the solution has been integrated, we provide comprehensive training for your teams. We also support you during the transition phase to ensure smooth and efficient adoption of the technology.

Through these different steps, we help you to take the next step towards optimized inventory management, enabling you to benefit fully from the advantages of RFID technology.

Investing in RFID technology

Spoiler alert: the hardware costs of an RFID solution are not as high as you might imagine!

Our 25 years of experience have shown us that the cost of implementing an RFID solution is always overestimated. An example will speak for itself.

One of our customers in the luxury goods industry produces around 3 million pieces / year. They wanted to identify and trace the movements of their parts through their main sites, and then take inventory when the parts leave the site and are distributed through boutiques around the world.

When the boutiques needed to replenish their stocks, the parts were inventoried, put on a cart and then loaded onto a truck before being sent to the boutique. On receipt at the boutique, the parts were again inventoried. Whether on delivery or on receipt, the inventory of around 500 pieces took a maximum of 2 minutes.

All data is fed back into the ERP system to validate receipt. Note that if a part is removed from the stock area before being inventoried, an alert is sent.

Customer benefit: Considerable time savings for operational staff, zero risk of error and enhanced security in terms of overall chain traceability.

Budget :

- Labels: 7 cts / label

- Infrastructure: CHF 20,000 (mobile and fixed antenna)

The ROI of this solution was calculated over a 15-month period.

What you need to know

RFID (Radio Frequency Identification) is transforming inventory management by enabling fast, accurate, contactless tracking of products.

Advantages of RFID inventory management :

- Considerable time savings: automatic or semi-automatic inventory, for example, of a 300m2 warehouse in 3 minutes.

- Improved accuracy: Elimination of manual counting errors.

- Cost savings: labor savings and reduction in costly errors.

- Enhanced security: RFID data is difficult to falsify.

- Automation and integration: easy integration of RFID data into existing management systems.

How it works : Tags, readers and software solution.

Implementation: Needs analysis, solution definition, customized software development, hardware installation and training.